The Volkswagen plant located in Kaluga is a very interesting place to visit. But it’s not opened for tourists and to enter it you must have a special invitation. So here you can see the exclusive photos of the most important parts of the plant: a shop where cars are assembled, a laboratory where they are tested for quality and a canteen.

Let’s start with the laboratory of quality control.

Many rules must be strictly followed here.

At the very entrance there stand the models of cars that are assembled entirely at the plant. These are two models of Volkswagen (the Polo Sedan and the Tiguan) and two models of Skoda (the Fabia and the Octavia).

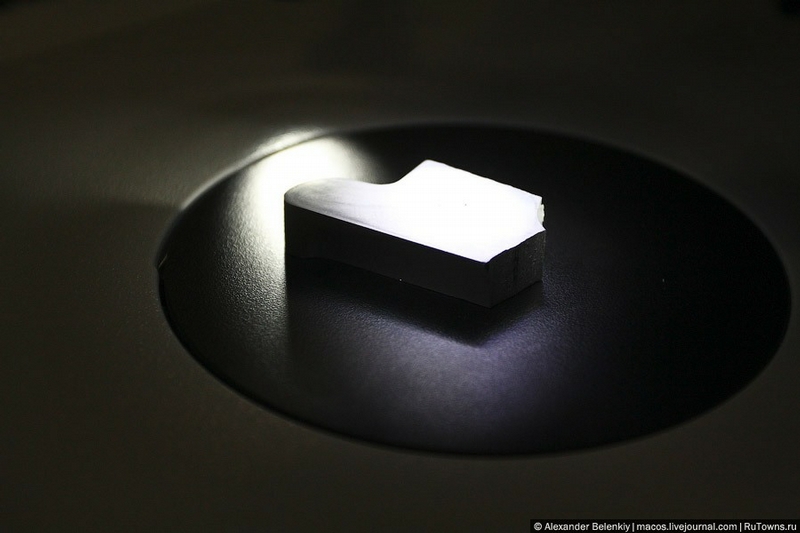

A model of the plant.

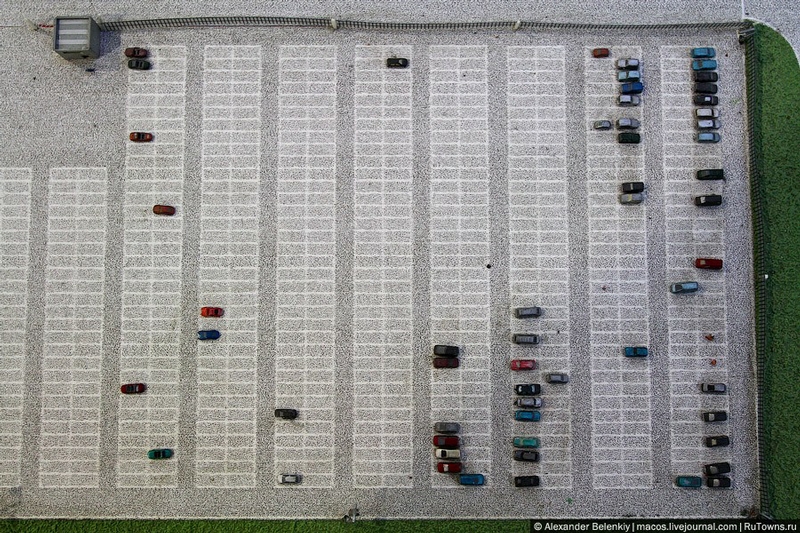

The Germans didn’t stint on the area. A rather large part of it is used by employees for parking. If it was a Russian company cars would probably be parked along the road because then the parking lot would cost money.

This lab is unique. None of Russian car plants has such a special unit that constantly monitors the quality of the cars. The pragmatic Germans take it for granted (as well as many other countries) but for Russia it’s quite unusual.

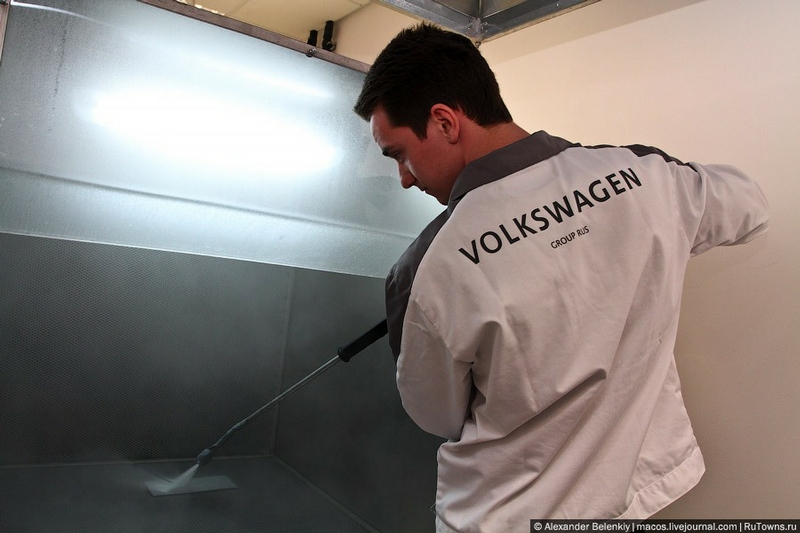

All conducted researches affect the future production throughout the world. And its employees are real scientists. They even wear white coats.

But at heart they are real hooligans. In a good sense of course. Most of their tests are intended to break, burn or spoil. Then they look at the results and give recommendations on how to make the car more resistant to such damage.

In this small stove upholstery is burnt. How many seconds will it take to burn it completely?

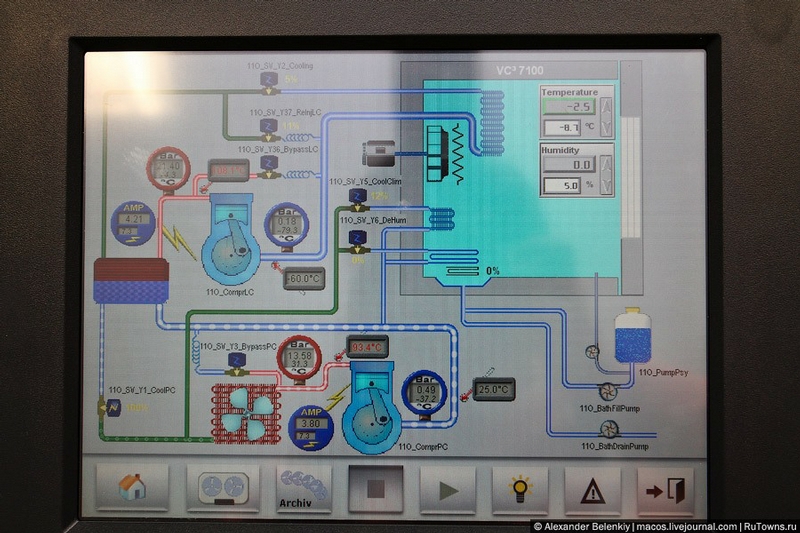

Equipment is not just expensive, but very expensive. Prices contain six zeros.

Sometimes testers take extreme measures: they damage the elements of a car with the help of the strongest mineral in the world – the diamond.

The diamond is also very expensive. It is stored in a safe and given to the testers just before the experiment.

The testers’ fantasy is really not limited. With this special cream, for example, they smear the parts of a car to figure out how they will react to the lady who makes up and moisturizes her hands every morning on her way to work.

The director of the lab opens a special container where details of a car are checked for their ability to resist corrosion.

Here details are covered by cuts with the help of a knife.

And then this damage is affected by steam to see what would happen with the paint film.

This is a stove and refrigerator at the same time. Details are placed here, then heated to the temperature of +40, and then cooled to the same temperature but with minus.

Having seen everything at the lab it’s time to move to the canteen.

On the way there is a very interesting room where the entire cars are broken. But this is a secret room and no one can enter it or even take pictures of it.

The canteen is the same as everywhere else.

Food for all employees and visitors is for free. You can choose salad, soup, the second coarse, a dessert and a drink. If you are not filled enough, you can buy something at the bar.

And this is the holy of holies of the plant – the place where cars are assembled.

The first stage is welding of a body. People here are only for monitoring, most of the work is performed by specialized robots.

Robots are yellow and scary. Look like giant hands or huge steel caterpillars from the fantastic movie.

Once the body is assembled and the doors are hung on it, it goes to the paint shop. There the car is dipped into a special bath and then dried. Everything is automated.

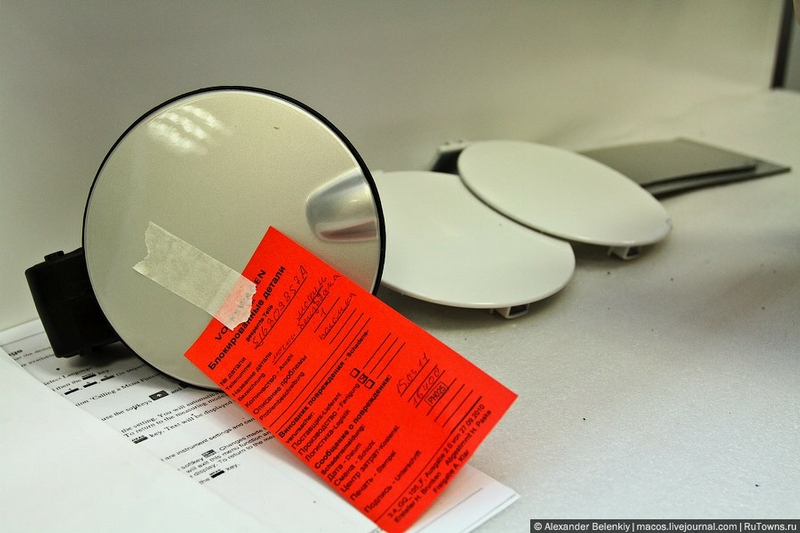

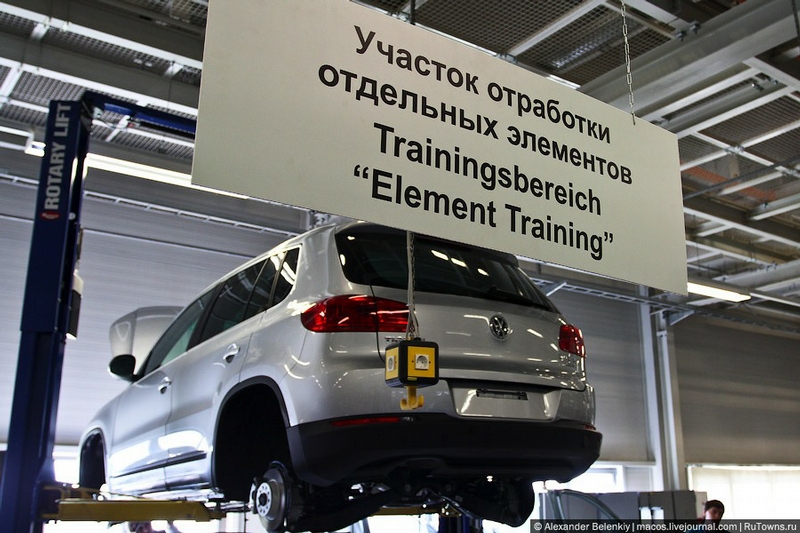

The area of separate details processing.

An assembly belt line goes through various areas. Somewhere dashboards and seats are fastened, somewhere wheels are installed.

Workers move sitting in such hanging chairs.

This is the warehouse of kits for assembly. The details are specially sorted in different sections.

The most intimate stage of production is a so-called “wedding”. When the “lower” part of the car with the engine is connected to the body.

And now some statistics. The plant makes 150 thousand cars per year. 4 of these models are assembled entirely at the plant.

By the way, the Polo Sedan has been designed specially for Russia.

No comments:

Post a Comment